|

We have been designing and building custom upenders and tilt tables for over 20 years. Over the course of that time, we have helped our customers achieve improved ergonomic access in a wide variety of applications ranging from tilting extremely dense cubes multiple times within a small footprint to very thin aluminum coils with product protection. We can lift, tilt, rotate, push, convey, and propel materials on a wide variety of custom designed upenders and tilters.

Our personnel have years of hands-on field experience which allows us to offer ideal solutions. We know what works, and even more importantly, what doesn't. Our customers can rest assured that not only will our designs and craftsmanship accomplish the task at hand but they will do so in an ergonomic, safe, and dependable way.

Our personnel have years of hands-on field experience which allows us to offer ideal solutions. We know what works, and even more importantly, what doesn't. Our customers can rest assured that not only will our designs and craftsmanship accomplish the task at hand but they will do so in an ergonomic, safe, and dependable way.

We can alter the platform length, width, and shape to your requirements with custom features such as engineered fixtures, stops and behavior.

We can rotate our upenders and tilters using a combination of inputs such as limit switches and photo eyes in conjunction with specialized controls.

We offer a wide range of base frame options including side and front fork pockets, extra lengths and widths as well as raised heights per specification.

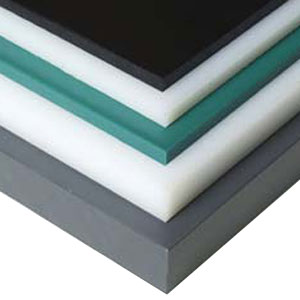

We can fabricate our upenders with the material types your application requires. Common selections are stainless steel, UHMW, rubber mating & special paints.

|

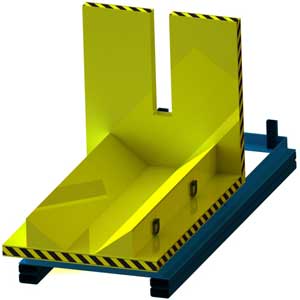

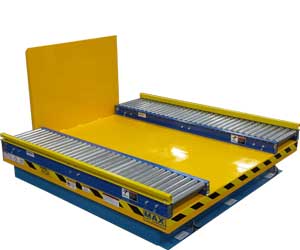

Long Deck

|

|

Long Deck |

|

|

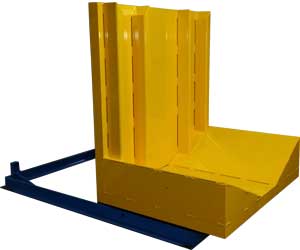

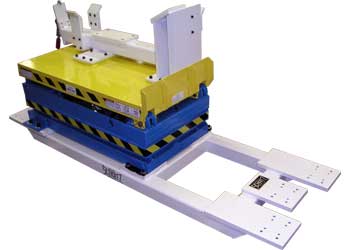

Fork Channels

|

|

Fork Channels |

|

|

Engine Tilter

|

|

Engine Tilter |

|

|

Extra Wide

|

|

Etra Wide |

|

|

Wide Conveyor

|

|

Wide Conveyor |

|

|

Pallet Gap

|

|

Pallet Gap |

|

|

Custom Fixture

|

|

Custom Fixture |

|

|

Fork Pockets

|

|

Fork Pockets |

|

|

Open Frame

|

|

Open Frame |

|

|

Butterfly

|

|

Butterfly |

|

|

Split Deck

|

|

Split Deck |

|

|

Ground Entry

|

|

Ground Entry |

|

|

Safety Skirting

|

|

Safety Skirting |

|

|

Split Conveyor

|

|

Split Conveyor |

|

|

Fixed Height

|

|

Fixed Height |

|

|

Wide Lift Tilt

|

|

Wide Lift Tilt |

|

|

Fixure Tilter

|

|

Fixture Tilter |

|