Company History |

In 1972 Bill knocked on the door of a local material handling distributor and asked the receptionist if they were hiring. While they were not looking for someone at that time, Bill managed to have a meeting with the owner. Impressed by his mechanical background, effective communication and, most importantly, his ambition, the owner created an opening for Bill a few weeks later. A position which would last for over 30 years with numerous national awards highlighting his industry knowledge and customer dedication.

During his time working as a material handling distributor, Bill encountered many applications where ergonomic access to the loads were an issue. The starting point for Lift Products came when a local graphics company needed a method of lifting pallets of paper stock in a level fashion. Bill came up with the idea of the Level Lifter and had an engineer draft the plans for the design. Lift Products was incorporated in December of 1994. Bill hired his sister Marguerite to manage accounts and his son to design the first lift table website on the Internet.

With the designs drawn and demand rising, an experienced and dedicated fabrication facility was required. Rich Davies was made a partner of Lift Products shortly after its formation. Rich's background in tool & die and production management would prove instrumental in the shaping of Lift Products identity as a manufacturer of custom designed ergonomic material handling equipment.

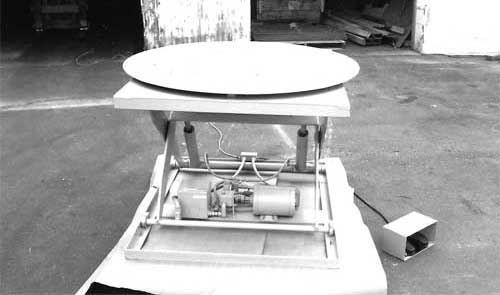

As time went on and Bill continued to make field calls, more and more opportunities arose for new equipment designs. The Roto-Max was a breakthrough moment for Lift Products as it was a unique design allowing 360 degree access to loads with a lowered height of only 6.5". Additional product designs such as the Moto-Cart and Max-Lift were quick to follow and Lift Products had to move from its humble closet sized office space to make enough room for additional personnel while the factory expanded with more specialized fabrication machinery and welding stations to meet growing demand.

While lifting, rotating, and transporting products and materials allowed for Lift Products to satisfy numerous ergonomic applications through it's early product offerings - one major aspect of work positioning was asked for time and time again, tilting. The Max-Tilt was designed and engineered to meet those requirements. Soon after, it was paired with the Max-Lift for lift and tilt applications.

The design of the Max-Tilt was proficient at handling pallet sizes in line with the platform lengths and widths of an industrial lift table but customer demands quickly scaled asking for heavier capacities and much larger deck sizes. The fundamental design parameters of the Max-Tilt were extended and engineered to create the Max-Upender with deck sizes up to 12 feet.

The fabrication experience gained in the customization of large upenders designed to tilt a wide range of different shapes and sizes lead to further customization of other product lines. Most notably, Lift Products started pairing as of then separate and distinct product lines into combined solutions such as self propelled lift tables for die handling. The LPMC was a combination of the Max-Lift and Moto-Cart for medium duty applications while the LPT-MGV paired an industrial pallet truck with the Max-Lift for heavy duty requirements.

Lift Products operates today much as it did in its formation. It is consistently gauging customer requirements and market demands to further improve on existing designs and introduce new methods of ergonomically handling products and goods in a variety of market sectors. We are always interested in hearing what our customers are doing and helping face the challenges they encounter through innovation and a dedication to quality, safety and repeatability.